|

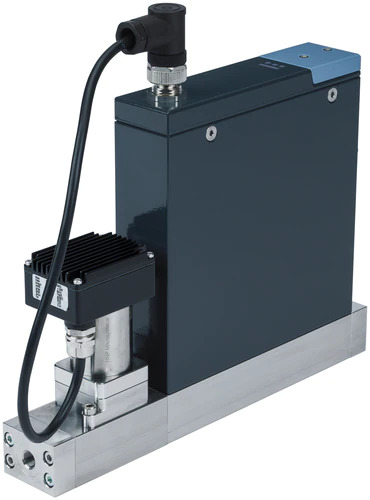

| Burkert Mass Flow Controller 8756 For Liquid |

Burkert Mass Flow Controller 8756 For Liquid are The mass flow controller (MFC) / mass flow meter (MFM) Type 8756 is particularly suitable for the very precise measurement or control of small quantities of liquid that also require a medium-separated sensor.

General Descriptions

The measuring principle of the sensor is based on the Coriolis effect and is completely independent of the medium. Pressure and temperature deviations have no impact on the measuring accuracy. In addition to the flow rate, the density and temperature of the liquid are measured. The device design enables a stable flow measurement that is immune to external impacts and does not require a zero-point adjustment when the process conditions change.

All materials that come into contact with the medium are highly resistant and enable use with a variety of liquids, whether aggressive or neutral media. Type 8756 is available in the variants • MFM • MFC with an interface for a modular actuator • MFC with integrated proportional valve • MFC with integrated micro annular gear pump. The high-precision pump is self-priming and the space in contact with the medium is sealed hermetically. It offers a very large control range and generates extremely low pulsations. This variant is used as a control or dosing system for liquids which have to be conveyed from an unpressurised container.

Type 8756 is available in the variants

- MFM

- MFC with an interface for a modular actuator

- MFC with integrated proportional valve

- MFC with integrated micro annular gear pump.

The high-precision pump is self-priming and the space in contact with the medium is sealed hermetically. It offers a very large control range and generates extremely low pulsations. This variant is used as a control or dosing system for liquids which have to be conveyed from an unpressurised container.

Burkert Mass Flow Controller 8756 General Technical Data

Product Properties

- Dimensions : Detailed information can be found in chapter “4. Dimensions” on page 5. Material1.)

- Housing : Aluminium

- Body (wetted): Stainless steel 1.4404 / 316L (optionally with inspection certificate 3.1 according to EN 10204)

- Sensor (wetted): Stainless steel 1.4404 / 316L

- Actuator (wetted): Detailed information can be found in the section actuator.

- Seals (wetted): FFKM, Metal or PCTFE

- Cleaning / Sterilisation (MFM version only)2.)

- With seal material FFKM or metal: Hot water (up to 90°C)

- With seal material FFKM: hot water (up to 90°C) and steam (up to 130°C)

- Configuration memory: Industrial μSIM card for easy device replacement

- Total mass: > 2 kg

- LED display: RGB-LED based on NAMUR NE107

- Software: Bürkert Communicator

Performance data

Maximum flow rate: 25 kg/h4

Nominal flow rate Q 5.)

- MFM Factory setting: 25 kg/h (can be reduced to a minimum of QNom = 1 kg/h) MFC with modular actuator

- interface Factory setting: 25 kg/h (can be reduced to a minimum of QNom = 1 kg/h) MFC with proportional valve

- Type 2873 Factory setting: 25 kg/h (can be reduced to a minimum of QNom = 4 kg/h)

- MFC with pump Factory setting: 8 kg/h (higher QNom on request; can be reduced to a minimum of QNom = 2kg/h)

- Minimum measurable flow rate Factory setting: 0.05 kg/h (can be reduced to a minimum of 0,01 kg/h)

- Maximum measuring range 1:500; measuring range depends on the set nominal flow rate QNom

- Maximum operating pressure (MFM): 100 bar(g) (for MFM with FFKM or PCTFE seals and port connection with G/NPT thread / otherwise 50 bar)

- Accuracy (flow): ± 0.2 % o.R. ± 0.0014 kg/h

- Repeatability (flow): ± 0.1 % o.R. ± 0.0007 kg/h

- Accuracy (density): ± 0.01 kg/l (with flow > 1.5 kg/h)

- Repeatability (density): ± 0.005 kg/l (with flow > 1.5 kg/h)

- Accuracy (temperature): ± 1.0 K (with flow > 1.5 kg/h)

- Repeatability (temperature):± 0.5 K (with flow > 1.5 kg/h)

- Response time (MFM): (t95 %)< 750 ms

- Settling time (MFC): (t95 %)< 1 s (depending on version)

- Leak integrity to the outside: < 10 - 6 mbar * l/s He (depending on seal material)

Burkert Mass Flow Controller 8756 Actuator

Micro annular gear pump Type 7620

- Smallest flow rate of the pump: 50 µl

- Differential pressure of the pump : 0…10 bar (Inlet pressure should be ≤ 5 bar(g), to avoid high leakage via the pump)

- Wetted parts: Stainless steel 1.4404 / 316L and 1.4462 / 318LN, Carbide (Ni based), Epoxy resin

Proportional valve Type 2873

- Nominal diameter: 0.8 mm

- Pressure range: Inlet pressure ≤ 5 bar(g)

- Wetted parts: Stainless steel 1.4404 / 316L, 1.4305 / 303, 1.4310 / 301 und 1.4303 / 305L, FFKM

Further control valves

In the modular version, any control valve can be controlled via the additional actuator output using a PWM signal (e.g. proportional valve Type 2871 or Type 2873). The integrated PI controller must be parameterised accordingly before commissioning (e.g. using Bürkert Communicator).

Electrical data

- Operating voltage: 24 V DC

- Voltage tolerance: ± 10 %

- Power consumption: < 5 W (as MFM)

- Residual ripple ± 10 % (for version with connected proportional valve ± 2 %)

Media Data

- Operating medium: Any neutral and aggressive liquids (chemical resistance of wetted parts assumed)

- Calibration medium: Water

- Medium temperature: - 10 °C…70 °C (as MFC: max. 60°C)

- Viscosity (dynamic): > 0.3 mPas (for version with pump: max. 200 mPas; for version with proportional valve:

- max. 40 mPas)

Process/Port Connection & Communication

Process connection: G ⅛, NPT ⅛, VCR ⅛, VCR ¼, compression fitting (⅛, ¼, 4 mm, 6 mm)

Electrical connection (options)

- CANopen or CANopen-based büS: 1x M12 plug, 5 pin

- Analogue: 0…20 mA, 4…20 mA 0…5 V, 0…10 V: 1x M12 plug, 5 pin, 1x M12 socket, 5 pin

- Industrial Ethernet: Planned, information on request

Burkert Mass Flow Controller 8756 Environment and Installation

- Ambient temperature: 0…50 °C (deviating temperature ranges on request)

- Installation position: Any (optimum installation position to avoid trapped gas bubbles is horizontally overhead or vertically with flow upwards)

- Protection class: IP65 and IP67; for MFC with pump: IP40

Environment and Installation

- The formulations of the components in contact with the medium do not contain any silicone components

- For 30 min. with the appliance unpowered, followed by a cooling time of 2 hours

- Exact description of the LED colours: see operating instructions

- For highly viscous media this value may not be achieved

- For MFC: To use the Autotune function QNom must be adjusted to the real achievable flow rate value